Polyethylene or polythene (IUPAC name polyethene or poly (methylene)) is the most widely used plastic, with an annual production of approximately 80 million metric tons. Its primary use is within packaging (plastic bag, plastic films etc.).

Polyethylene is a thermoplastic polymer consisting of long chains produced by combing the ingredient monomer ethylene (IUPAC name ethene), the name comes from the ingredient and not the actual chemical resulting.

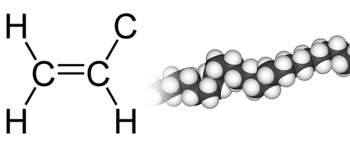

The ethene molecule (known almost universally by its common name ethylene) C2H4 is CH2=CH2, Two CH2 groups connected by a double bond, thus:

Polyethylene contains the chemical elements carbon and hydrogen.

Polyethylene is created through polymerization of ethene. It can be produced through radical polymerization, anionic addition polymerization, ion coordination polymerization or cationic addition polymerization. This is because ethene does not have any substituent groups that influence the stability of the propagation head of the polymer. Each of these methods results in a different type of polyethylene.

Polyethylene is classified into several different categories based mostly on its density and branching. The mechanical properties of PE depend significantly on variables such as the extent and type of branching, the crystal structure and the molecular weight. With regard to sold volumes, the most important polyethylene grades are HDPE, LLDPE and LDPE.

- Ultra high molecular weight polyethylene (UHMWPE)

- Ultra low molecular weight polyethylene (ULMWPE or PE-WAX)

- High molecular weight polyethylene (HMWPE)

- High density polyethylene (HDPE)

- High density cross-linked polyethylene (HDXLPE)

- Cross-linked polyethylene (PEX or XLPE)

- Medium density polyethylene (MDPE)

- Linear low density polyethylene (LLDPE)

- Low density polyethylene (LDPE)

- Very low density polyethylene (VLDPE)

PE WPC is used for making high density and rough applications in exteriors. PE WPC can give products like decking including flooring, lumber, moulding strips, furniture materials, wall cladding, hollow boards, hollow filler sections and profiles.